Rotary Screw Compressors

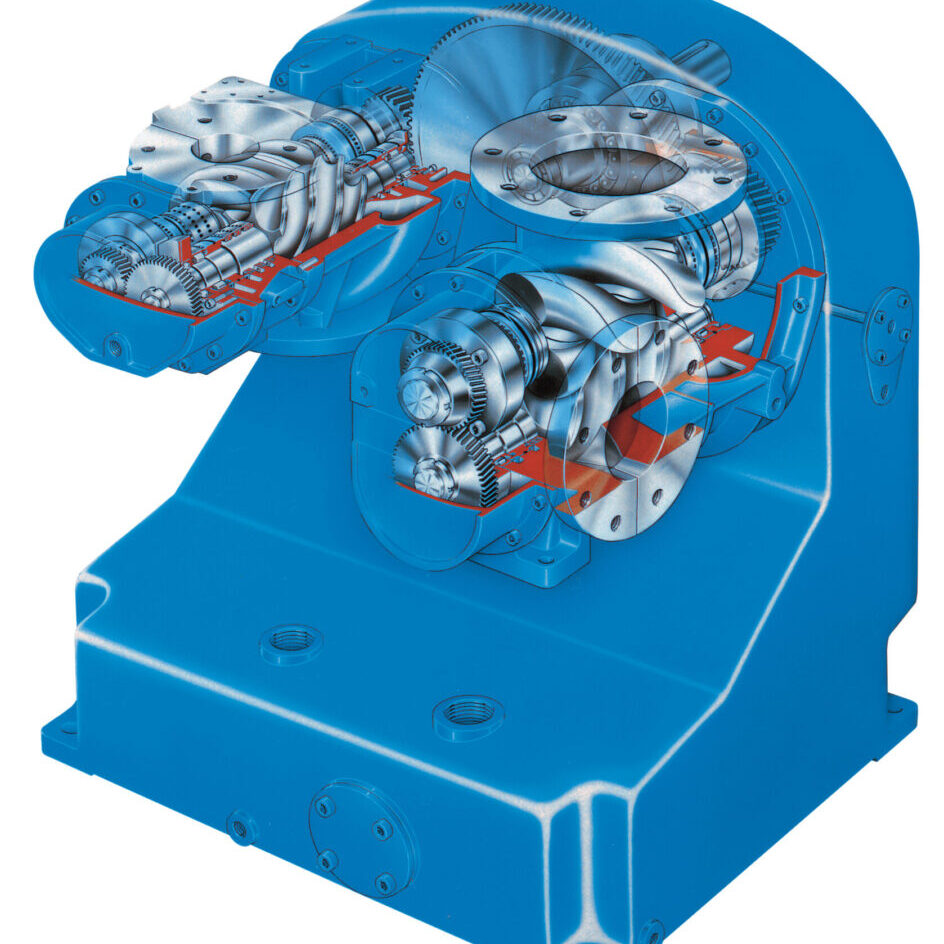

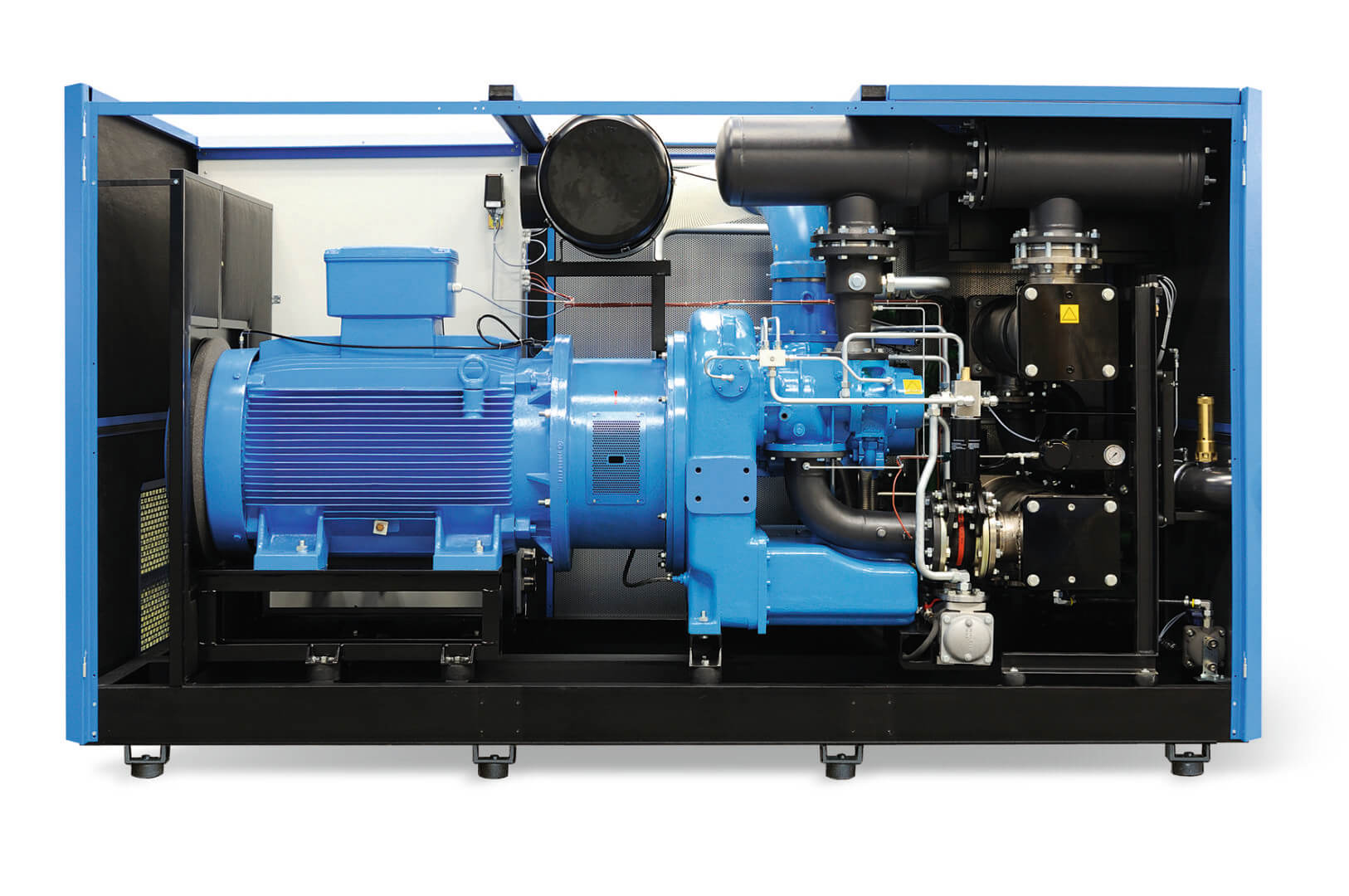

Oil Injected Rotary Screw Compressor:

- Rotary screw compressor is a positive displacement type, which means that a given quantity of air or gas is trapped in a compression chamber and the space which it occupies is mechanically reduced, causing a corresponding rise in pressure prior to discharge. The oil injected rotary screw compressor consists of two intermeshing rotors in a stator housing having an inlet port at one end and a discharge port at the other. The male rotor has lobes formed helically along its length while the female rotor has corresponding helical grooves or flutes. The number of helical lobes and grooves may vary in otherwise similar designs. Air flowing in through the inlet port fills the spaces between the lobes on each rotor. Rotation then causes the air to be trapped between the lobes and the stator as the inter-lobe spaces pass beyond the inlet port. As rotation continues, a lobe on one rotor rolls into a groove on the other rotor and the point of intermeshing moves progressively along the axial length of the rotors, reducing the space occupied by the air, resulting in increased pressure. Compression continues until the inter-lobe spaces are exposed to the discharge port when the compressed air is discharged. Oil-Injected rotary compressors are packaged with all required components to ensure safe and reliable operation.

- The principles of an oil injected rotary screw - Oil is injected into the compression chamber during compression and serves three basic functions: 1. It lubricates the intermeshing rotors and associated bearings. 2. It takes away most of the heat caused by compression. 3. It acts as a seal in the clearances between the meshing rotors and between rotors and stator. The air from the atmosphere enters the intake filter and the intake valve to the airend where oil is also injected for cooling, lubrication and sealing, then the air oil mixture goes to the air oil separator tank where the oil is separated from air in the tank and the separator element. The air then passes through the minimum pressure valve to the after cooler and out to the plant for use. The oil separated in the tank goes to the oil cooler to the oil filter and again injected back to the air end. The pressure required for the oil flow is maintained by the minimum pressure valve mounted on the separator tank. The oil scavenger line is to make sure the oil, which remains in the separator element, is retuned back to the air end. The thermal valve in the circuit is to maintain the oil temperature at a certain level to avoid condensation. When the oil temperature is lower than the required limit, the oil will not go to the oil cooler and will directly be injected in the airend to maintain the oil temperature.

Oil Free Rotary Screw Compressors:

- The oil free rotary screw compressor also is a positive displacement type of compressor. The principle of compression is similar to that of the oil injected rotary screw compressor but without oil being introduced into the compression chamber. Two distinct types are available - the dry type and the water injected type.

- In the Dry Type, the intermeshing rotors are not allowed to touch and their relative positions are maintained by means of lubricated timing gears external to the compression chamber. Since there is no injected fluid to remove the heat of compression, most designs use two stages of compression with an intercooler between the stages and an aftercooler after the second stage. The lack of a sealing fluid also requires higher rotative speeds than for the oil injected type.

- In the Water Injected Type, similar timing gear construction is used but water is injected into the compression chamber to act as a seal in internal clearances and to remove the heat of compression. This allows pressures in the 100 to 150 psig range to be accomplished with only one stage. The injected water, together with condensed moisture from the atmosphere, is removed from the discharged compressed air by a conventional moisture separation device. Similar to the oil injected type, oil free rotary screw compressors generally are packaged with required components to ensure safe and reliable operation.